Are your business cards causing harm to the planet? As business professionals, we all strive to make a positive impact in the world. While it might not be immediately obvious, even something as seemingly innocuous as ordering and giving out business cards has an environmental effect that is worth considering. Especially since we’ve seen an increase in the amount of people claiming that their cards are eco because they use recycled paper or bio-degradable laminate.

In this blog post, we will explore the environmental impacts of using business cards, including the materials used for production, paper waste caused by use and disposal of printed products — as well as alternative approaches that organizations can take foster sustainable networking practices instead.

The paper

The main resource in a business card is paper so we will mainly focus this article on this resource. The majority of paper comes from trees, that’s a great start, but do we really know what that looks like? It becomes especially confusing when companies use ‘ethically sourced trees’ or recycled paper to produce their paper.

So let’s straighten out some facts. For this article we will be focusing on the UK and the EU as they have some of the best forestry regulations in the world and it’s only fair to acknowledge this as the paper mill industry has taken massive strides in being more environmentally friendly. So let’s discuss the best case scenario.

Recycled paper isn’t really 100% recycled paper.

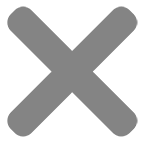

The average recycled paper requires virgin pulp to be added when creating to re-introduce structure and stability to the structure of the paper. To create recycled paper, currently UK paper mills use 70% paper pulp from recycled sources and 30% of wood pulp from new trees.

70% recycled paper pulp used in creating new paper can’t really be improved for one major reason. Each time paper is recycled the fibres loose integrity and eventually become useless. It’s this reason that we will always need freshly grown trees to mix with recycled pulp to create recycled paper.

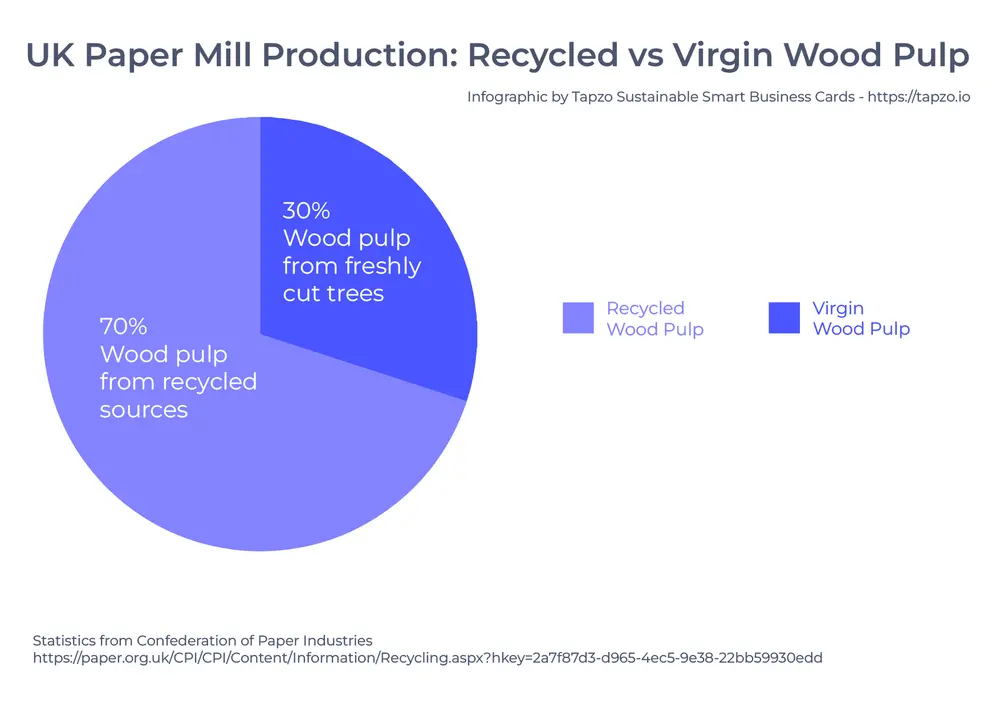

30% new tree pulp needing to be used is 1,000,000 tonnes of wood pulp each year in the UK. Of which 0.8 million tonnes of this pulp is imported into the UK from countries that may not have the best forestry practises as we do.

Growing trees to cut them down

So should we really be cutting trees? Well yes and no. We’re not oblivious to the fact that we will always need paper. But it’s vital that we reduce our reliability towards paper if we wish to actually reduce environmental damage and grow our forests in the UK.

No matter how you want to put it, cutting trees is still cutting trees.

Trees are habitats for wildlife that further benefit our environment. Trees are the world’s lungs, they absorb carbon and produce oxygen. The act of cutting them destroys this. What’s more is the machinery used to cut and transport the trees, further destroys the habitat’s of wildlife in the forest.

These days most trees used in paper production are specifically grown in forests for the purpose of creating paper. Fast growing softwoods are grown to support the demand.

At first observation this seems fine, however with any ecosystem, there needs to be balance. We can’t simply clear forests of native species and replace with one monoculture. When a forest is predominantly biased to one species, you open the door to catastrophic risk. Disease and pests flourish in these forests.

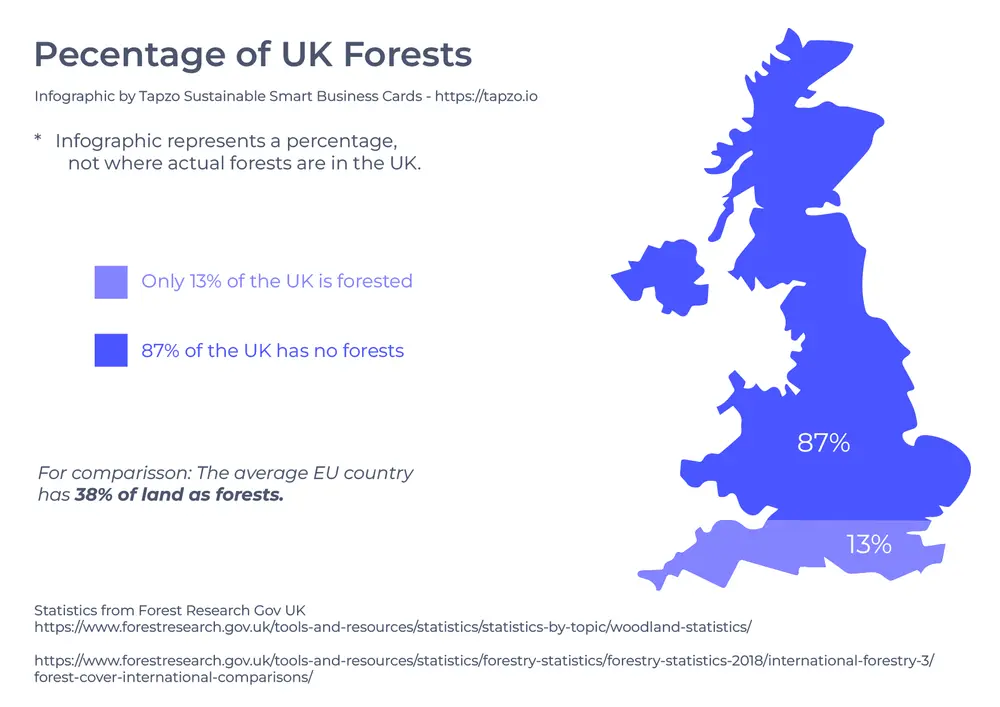

Only 13% of the UK is currently forests. This is well below the EU average of 38%, and 31% worldwide.

What’s more concerning is that 20% of all the forests in the UK are ash trees which are currently dying at a vast rate due to an unstoppable fungus disease. It’s estimated that in the next 30 years we will loose 90% of all ash trees in the UK. This would leave the UK with forest’s covering only 9.6% of the UK.

The energy used making paper

The production of paper is an incredibly energy-intensive process. To produce recycled paper it takes 31% less energy than producing brand new paper. Which is great, but it’s easy to be mislead that this is somehow good for the planet.

If the question was what’s better; brand new paper or recycled paper, it’s a no brainer. Of course recycled is better. Less trees have to be cut down, less energy and water used, less greenhouse gasses. The list goes on. However, and it’s a big however…

Producing paper, no matter whether its brand new or recycled consumes A LOT of energy. Energy that already is in short supply.

The water wasted making paper

Water is used in vast quantities creating paper. The amount differs depending on whether it’s brand new paper or recycled.

Producing brand new pulp-based paper requires 40,000 litres of water per tonne, but when fibres are reused and recycled in the manufacturing process this amount is reduced to 24,000 litres of water- leading to a massive 47% cut down on resource consumption.

Producing recycled paper is far more sustainable than brand new paper, however it’s easy to oversee the environmental impact of recycled paper.

Reducing resources is sexy, it means it’s more sustainable but also more profitable / cheaper. But reducing doesn’t mean that you’re not still using a lot of resources. 24,000 litres of water to produce just a tonne of pulp is still a huge amount!

To put it in perspective; The UK Paper Industry produced 3.63 million tonnes of paper in 2020.

Paper pulp has a yield factor of 90% which means that 1 tonne of pulp would make 900kg of paper.

This means the UK paper industry that produced 3.63 million tonnes of paper, used 3.99 million tonnes of paper pulp to produce that paper, which would have used just over 95 billion litres of water in the process.

Don’t panic, it’s not all doom and gloom! Paper mills process the water used in making paper pulp. They clean the water from all chemicals used such as bleach and return 90% of the water used back into the water system. So out of the 95 billion water used in 2020 by the UK paper mill industry, 85.5 billion litres of water would have been returned to the water systems. Meaning technically only 9.5 billion litres of water was wasted. Still a lot, but not as bad as the jaw dropping 95 billion.

The laminate

The laminate that coats the average business card tends to be made out of plastic which makes the paper card completely non recyclable. (Similar to the inside of a disposable coffee cup)

Now luckily there are biodegradable alternatives which are growing quickly in popularity, however there are a few flaws which we’ll get into later.

Currently there are 3 main biodegradable laminate alternatives:

Cellogreen: Cellogreen is a film product made from the organic compound cellulose, which is biodegradable and recyclable.

Polylactic Acid (PLA): Polylactic Acid is a polyester that comes from starch or sugar cane. However, decomposition of PLA may take a longer time than other alternatives depending on the environmental conditions.

Oxo-Biodegradable Plastic: Oxo-Biodegradable Plastic is composed of conventional plastics such as polyethylene, polypropylene, and polystyrene. In order to make this sustainable, additives are included to break down the chemicals in plastics.

Challenges with Biodegradable Lamination

While biodegradable lamination is starting to grow in popularity, there are a few challenges associated with its use.

- The quality of biodegradable lamination may not be as great as its plastic counterpart in terms of protecting the artwork that’s printed. While it does the job, scratches and scuffs may be more obvious.

- Biodegradable plastics take a long time to decompose. In addition, some plastics may need specific conditions in order to decompose, such as a high temperature or UV strength.

- Although a more sustainable option, biodegradable plastics can be more expensive than standard plastics. This causes businesses to occasionally turn their back on the eco-friendly option and opt for the cheaper alternative.

- The key challenge in recycling lies in separating the laminates from one another, different laminates require different approaches to recycle. Business cards don’t come with this information printed on them so recycling facilities have no way of knowing that your business card has a biodegradable laminate that is recyclable.

- What might not be as obvious is that we’re still having to create a product. Whether it’s biodegradable or not. There’s no question that biodegradable is amazing, but energy and resources still had to be used to to create this magical laminate.

The ink

Printer inks are composed of a variety of components, many with potential to be hazardous both for you and the environment.

A few examples include butyl urea that prevents paper curling; cyclohexanone which boosts ink adhesion on polymers surfaces; diverse dyes such as reactive red 23 dye, acid yellow 23 dye and direct blue 199 containing sulphur compounds; ethoxylated acetylenic diols modifying water surface tension along colours structures; EDTA full of contaminants plus Ethylene glycol.

What about water based inks?

Water based inks are praised for their eco-friendly properties, yet they may contain dangerous chemicals such as formaldehyde, oil and alcohol. If present in high concentrations these substances can be labeled hazardous materials – requiring specialized handling to ensure safety.

What about soy based inks?

Vegetable-based inks often utilize high concentrations of petroleum to maintain their vivid colors.

In order for ink to carry the Soy Seal logo, (classified as a soy ink) it must contain a surprisingly low 6 to 40 percent soy-based oil – a percent that varies depending on its intended use.

Furthermore Soy is a major crop worldwide used in conventional agriculture’s monoculture system. This comes at an immense cost that limits biodiversity and inhibits ecosystem resiliency.

Greenhouse gasses

The paper industry is a major contributor to carbon dioxide emissions, with 9% of global manufacturing output coming from the sector.

Despite the efforts of recycling, paper is still a major factor in contributing to landfills.

In fact, it accounts for nearly 25% of landfill mass and its degradation releases harmful methane into our atmosphere – further adding to global warming. We must be diligent about reducing our paper waste if we want a safe future.

Business cards causing harm to the planet

The hard truth to swallow is that the act of creating a product that is disposable will never be environmentally friendly. We can put a plaster on the problem by using recycled, biodegradable, eco resources to create our paper, laminates and inks but the problem will still exist. These resources don’t just appear out of thin air.

We live in a world where we care about the environment, but do we actually care or do we like the idea of caring? What we mean by this is that; we tend to see a label ‘recycled paper’ or ‘biodegradable’ and are happy to just trust that label as if it’s some sort of seal of approval that you’re doing good for the planet. You’re not. You’re doing better for the planet but not good. If your starting point is terrible and you do better, that doesn’t mean you’re doing good, it just means you’re doing less terrible.

Real change will only come from changing our behaviour with how we interact with products. We will always need paper, but do we always need to use paper?

Smart sustainable business cards

So we can aknowledge that our behaviour must change to start making a positive impact but what does this look like? We still need business cards to network and exchange contact details…

Well at Tapzo we create awesome, smart sustainable business cards. We’ve re-imagined the behaviour of business cards.

Instead of handing over a disposable business card that will end up in landfill, our smart business cards exchange details by tapping the card onto a smartphone. Allowing your details to be downloaded directly onto that smartphone’s contacts book.

Our smart business card is a one card for life solution, a business card that you re-use and keep forever. Updating details online instantly instead of re-printing a new batch of cards, say goodbye to re-printing forever.

We’ve transformed a disposable product that is printed in vast quantities and requires resources to create, that ultimately ends up in landfill. To a product that requires just the one card, yes resources to create but lasts a lifetime that you re-use.

If you’re interested in learning more about the other smart benefits of a Tapzo smart business card, check out this page.